On May 23, 2025, the customer from UAE who has been engaged in road guardrail industry for nearly 20 years visited Liaocheng, Shandong to visit Shandong Safebuild beam guardrail and new type rotary barrier. Both sides had a detailed discussion and exchanged opinions on the product production process and guardrail standard requirements.

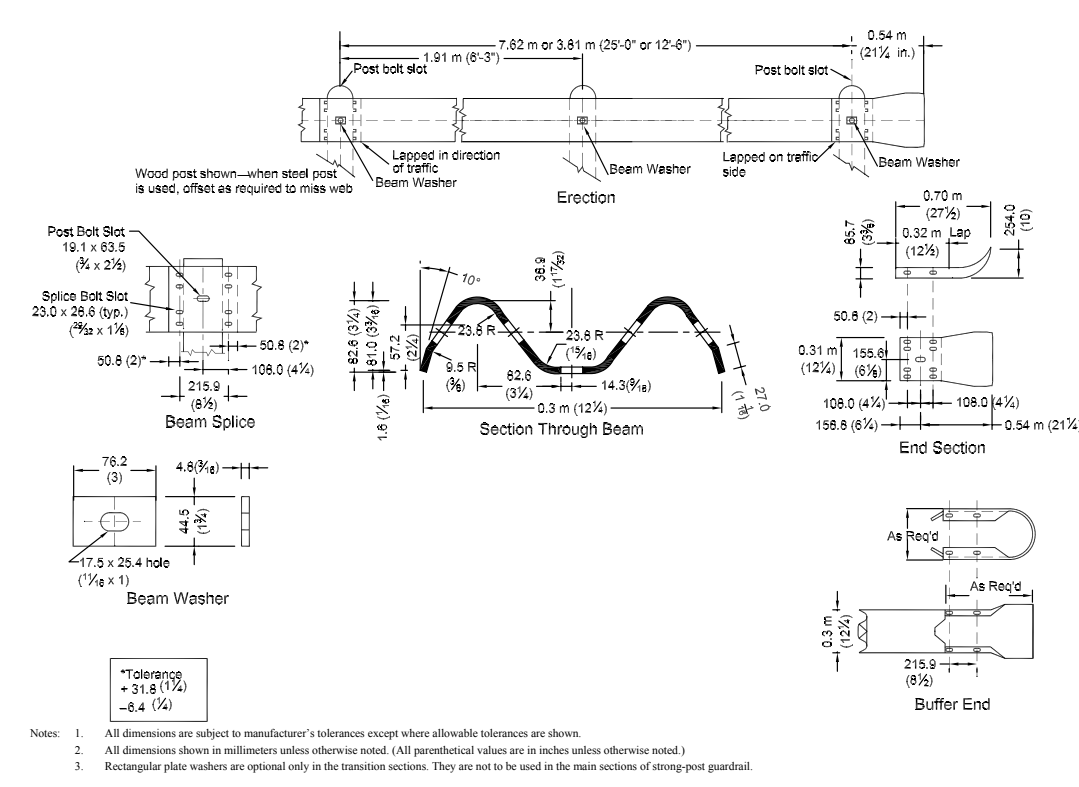

After communication, the customer requested to produce the guardrail in strict accordance with the American road guardrail standard. There are strict requirements on the size, thickness, surface treatment, hot-dip galvanizing thickness of the guardrail, post and other main components, and the finished products of Safebuild workshop were measured in detail at the site, and they were very satisfied with the results.

Safebuild company has extensive experience in the production of guardrails and is familiar with the safety standards for road guardrails in various regions around the world. The American standard, as one of the major global standards, has provided Safebuild company with rich experience in the production of American-style guardrails.

The full name of the American Standard of the highway guardrial is: Corrugated Sheet Steel Beams for Highway Guardrail AASHTO Designation: M 180-00 (2004)

The standard cites the following four documents:

AASHTO Standards ASTM Standards ANSI Standards Military Standard

The standard is divided into the following four categories based on the zinc coating and thickness of the guardrail:

(1)Surface Finish Type:

Type I—Zinc coated, 550 g/m2 (1.80 oz/ft2) minimum single-spot.

Type II—Zinc coated, 1100 g/m2(3.60 oz/ft2) minimum single-spot.

Type III—Beams to be painted.

Type IV—Beams of corrosion resistant steel.

(2)Level Type:

Class A—Base metal nominal thickness—2.67 mm (0.105 in.).

Class B—Base metal nominal thickness—3.43 mm (0.135 in.).

Mechanical properties of the highway guardrail system is:

(1) Beams and transition sections:

Yield Point, minimum, 345 MPa (50000 psi);

Tensile Strength, minimum 483 MPa (70000 psi); and

Elongation, in 50 mm (2 in.), minimum, 12 percent.

(2) End and buffer sections:

Yield Point, minimum, 227 MPa (33000 psi); and

Tensile Strength, minimum 310 MPa (45000 psi).